Technical Documentation

Translating complex information into clear, precise, and actionable documentation.

Documentation for Product Development

Technical Requirements

Our Technical Requirements service ensures every project begins with a clear, unambiguous foundation. We capture functional, regulatory, and performance criteria in structured, traceable documents that align all stakeholders. This minimizes misinterpretation, reduces costly rework, and sets the standard for design and validation phases. With a disciplined approach to requirements definition and management, we help ensure that your product meets expectations, complies with industry standards, and is engineered for success from day one.

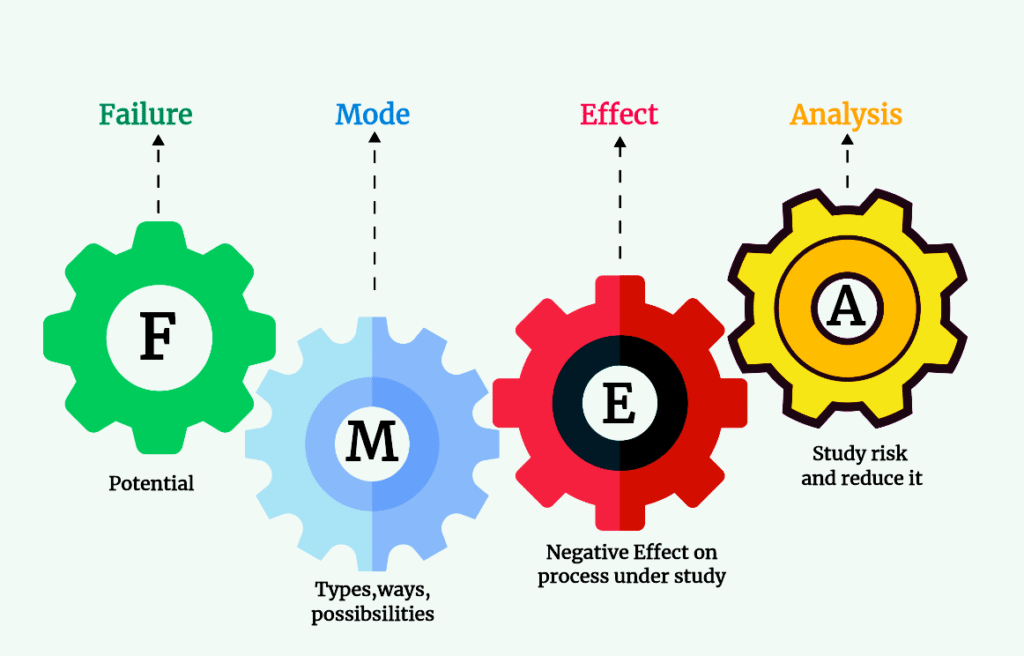

Failure Modes and Effects Analysis (FMEA)

We specialize in FMEA to identify potential risks before they become real-world issues. By systematically analyzing possible failure modes, their effects, and likelihood, we prioritize corrective actions early in the design or process stage. This structured methodology enhances reliability, reduces downtime, and safeguards compliance with industry standards. Our team supports both DFMEA (design) and PFMEA (process), empowering clients to launch safer, more dependable products while minimizing warranty costs and customer complaints.

Design Validation Plan and Report (DVP&R)

Our DVP&R service ensures that products are thoroughly validated before reaching the market. We design detailed validation plans that define testing methods, acceptance criteria, and reporting structures, guaranteeing traceability from requirement to test result. By capturing results in structured reports, we provide confidence that the design meets both regulatory and customer expectations. This systematic approach shortens approval cycles, reduces risks, and ensures that every product is market-ready with full compliance.

Test Plans, Design of Experiments (DoE)

With our Test Plans & DoE services, we take a scientific approach to product testing and optimization. We design structured test campaigns that maximize data output while minimizing time and cost. Using statistical techniques, we identify key variables, optimize performance, and ensure reproducible results. This approach reduces uncertainty, supports data-driven decisions, and builds confidence in product reliability. From laboratory validation to field trials, our service accelerates development while reducing risk.

Technical Documentation

We deliver complete Technical Documentation packages that support your product throughout its lifecycle. Our documentation covers specifications, datasheets, compliance reports, and certification-ready submissions, tailored to your industry standards. With clarity, consistency, and attention to detail, we enable smooth communication across engineering, manufacturing, suppliers, and regulatory bodies. The result is reduced ambiguity, faster approvals, and a comprehensive knowledge base that ensures long-term product support.

Product Development Framework

Our Product Development Framework service provides structure to complex projects, integrating best practices, stage gates, and clear deliverables. By establishing workflows that balance flexibility with discipline, we improve collaboration across teams and reduce development risks. The framework promotes accountability, improves decision-making, and ensures projects move forward with clarity. Clients benefit from faster time-to-market, reduced rework, and stronger alignment between strategic goals and engineering execution.

System Interface Diagrams

We prepare System Interface Diagrams that clearly illustrate interactions between components, subsystems, and external systems. These diagrams reduce integration risks by highlighting dependencies and constraints early in the process. By providing a single source of truth for system interactions, they improve cross-functional communication and prevent costly errors during testing and commissioning. Our structured approach ensures seamless integration across complex engineering environments.

Install and O&M Manual

Our Installation & O&M Manuals are designed to make complex systems simple to operate and maintain. We combine technical accuracy with clear instructions, structured layouts, and illustrative graphics to support end-users, operators, and maintenance teams. Manuals are built to reduce downtime, minimize training requirements, and extend the product lifecycle. With a focus on usability and compliance, we provide documentation that enhances safety, reliability, and customer satisfaction.

Process Capability Calculations

Our Process Capability Calculations (Cp, Cpk) service assesses the consistency and predictability of manufacturing processes. By analyzing process data against specification limits, we provide actionable insights into quality performance and readiness for scaling. This helps identify variations, highlight areas for improvement, and support data-driven decision making. Clients gain confidence that processes are capable of producing parts reliably, reducing scrap, rework, and associated costs.

Graphical Assembly Instructions (Task Cards)

We create Graphical Assembly Instructions (Task Cards) that simplify complex assembly steps into clear, intuitive visuals. By combining annotated diagrams, exploded views, and step-by-step sequences, we reduce reliance on lengthy text and minimize training requirements. This improves assembly speed, reduces errors, and ensures consistency across operators and sites. Task cards are especially valuable for global teams, enabling quick understanding without language barriers.

Service Bulletins

Our Service Bulletins keep your customers, service teams, and regulatory bodies informed with timely, clear updates. Whether announcing product improvements, maintenance actions, or safety notices, we prepare bulletins that are structured, concise, and compliant with industry standards. This ensures effective communication, faster response to issues, and improved customer trust. Our service bulletins help extend product life and support brand reputation through proactive engagement.

System Information Sheets

We provide System Information Sheets that condense critical data into concise, easy-to-use references. Covering technical specifications, operational limits, and safety information, these sheets support quick decision-making in the field. By combining clarity with precision, they ensure stakeholders—from operators to managers—have the right information at their fingertips. This service improves efficiency, reduces errors, and enhances system understanding across the lifecycle.

Construction Documentation

Method Statements

Our Method Statements outline safe, structured procedures for executing construction and engineering tasks. They cover step-by-step activities, required resources, risk assessments, and quality controls. By providing clear documentation, we ensure compliance with safety standards, reduce risks, and improve site productivity. These documents become essential tools for training teams, coordinating subcontractors, and demonstrating due diligence to regulators and clients alike.

Technical Queries (RFIs, TQs)

We manage Technical Queries (RFIs/TQs) to ensure clarity and traceability in construction projects. Our structured process documents questions, responses, and resolutions, eliminating ambiguity and reducing costly delays. With our approach, communication between contractors, designers, and clients is streamlined, and design intent is preserved. This ensures that queries are closed quickly and effectively, supporting smooth project progress and regulatory compliance.

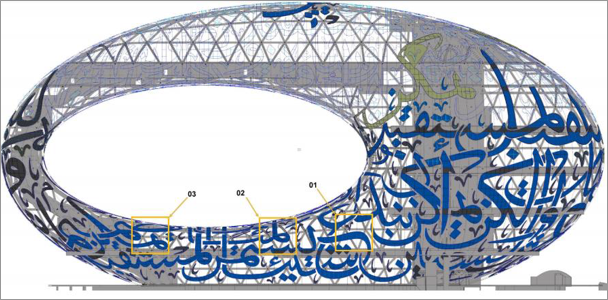

BIM Coordination

Our BIM Coordination service ensures multidisciplinary models are accurate, clash-free, and aligned across stakeholders. We facilitate model integration, run clash detections, and generate coordination reports that highlight conflicts and solutions. This reduces construction errors, avoids costly rework, and improves project predictability. With structured workflows and collaboration tools, we help teams leverage BIM as a central hub for efficient design, planning, and construction.

Safety Documentation

Safety Requirements Analysis

We perform Safety Requirements Analysis to identify safety-critical functions, compliance obligations, and associated risks early in the lifecycle. By embedding safety into design and documentation, we minimize hazards and ensure regulatory alignment. This structured approach supports certification, builds user trust, and enhances overall product reliability.

Workpack & SOPs

Our Workpacks and SOPs combine task-specific instructions with broader procedural guidance to ensure safe and consistent execution. We prepare detailed step-by-step documents, including required tools, safety checks, and quality measures. This reduces training time, minimizes human error, and ensures compliance with industry standards. Clients benefit from safer operations, improved efficiency, and documented proof of due diligence.

SSoWs, RAMS

We develop Safe Systems of Work (SSoWs) and Risk Assessments & Method Statements (RAMS) to support safe, compliant operations across industries. These documents identify hazards, define control measures, and outline approved methods of work. By integrating regulatory requirements with practical site procedures, we ensure legal compliance and worker protection. The result is reduced accidents, stronger safety culture, and improved confidence for clients and regulators.

Let’s Bring Your Idea to Life

Get in Touch

If you have any questions or would like a project quote, please email us at info@crafizsolutions.co.uk or use the contact form.