Architectural Design

Engineered architectural solutions—designed, optimised, and documented for modern construction.

Architectural Engineering

Concept Design

Our Concept Design service transforms initial ideas into clear, feasible design directions supported by technical considerations and practical constraints. We help define architectural intent through early sketches, massing studies, façade concepts, and functional layouts, ensuring every proposal aligns with project requirements and available technologies. By integrating constructability analysis and early coordination with structural and façade teams, we reduce design risks and ensure smoother transitions into detailed engineering. Visualisations, diagrams, and preliminary models support effective communication with stakeholders, enabling informed decisions at early project stages. Our approach combines creativity with engineering discipline, ensuring a strong conceptual foundation for the entire design process.

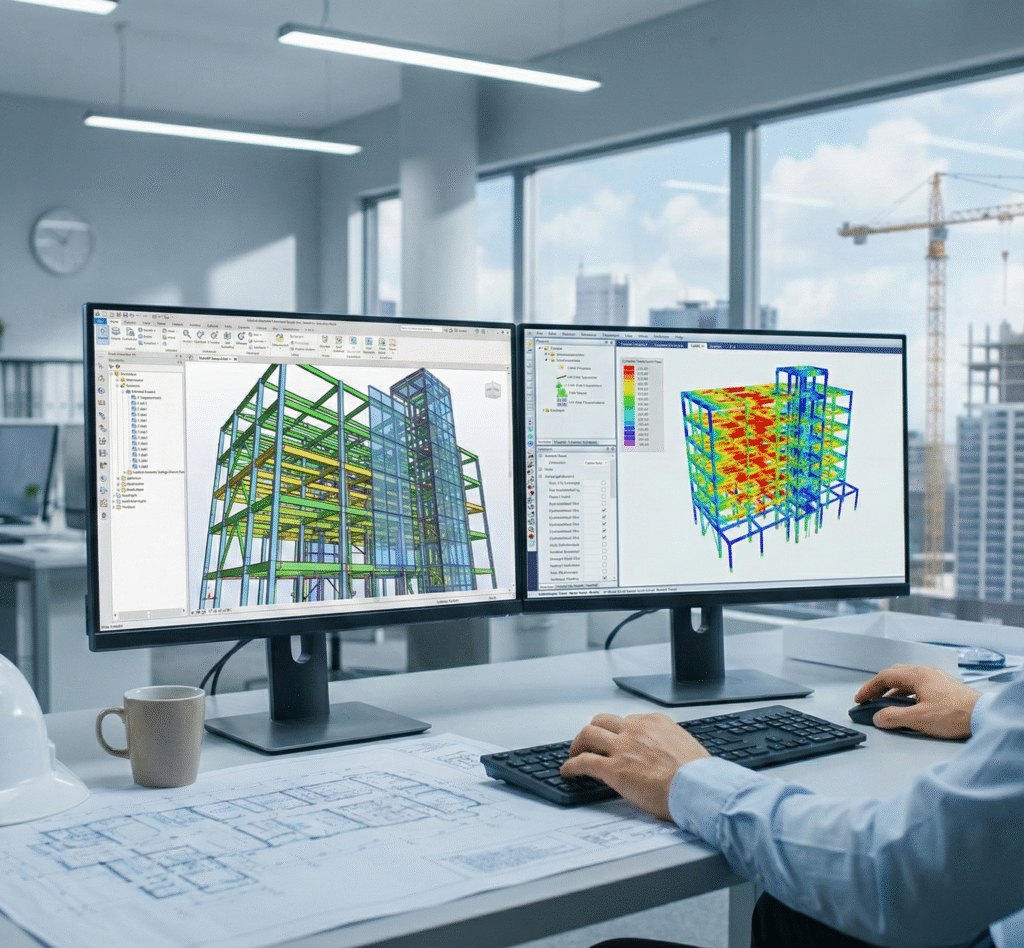

Structural Engineering

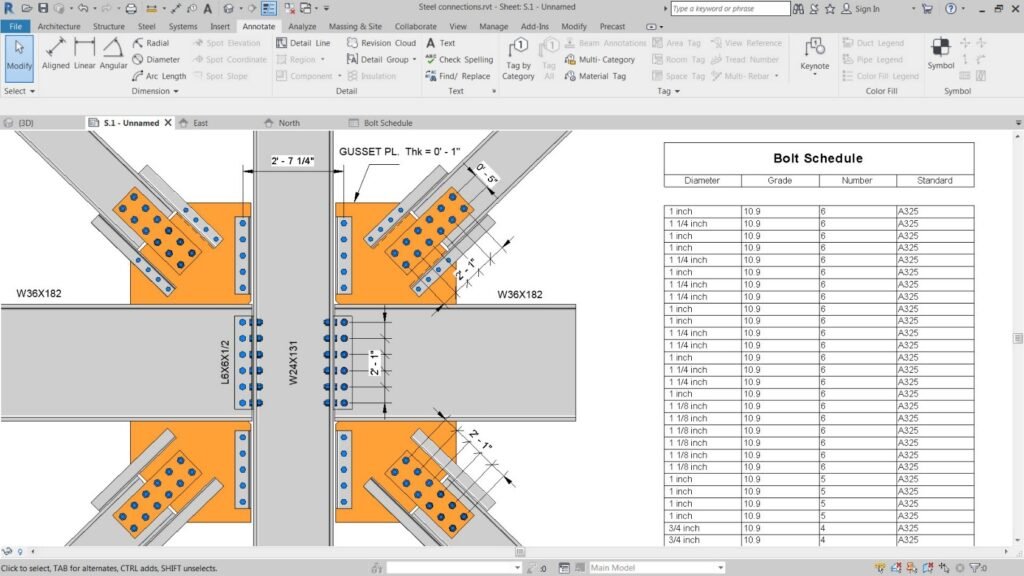

We provide structural engineering services tailored for architectural projects, bespoke structures, and advanced façades. Our team performs detailed analysis, load evaluations, material optimisation, and connection design while ensuring compliance with relevant codes and safety standards. We work closely with architects and fabricators to refine structural systems that meet both aesthetic and practical needs. Whether supporting lightweight assemblies, complex geometries, or integrated façade systems, we focus on efficiency, buildability, and long-term reliability. Using advanced modelling and simulation tools, we produce clear structural layouts, calculation summaries, and coordinated details that streamline fabrication and installation. This helps minimise redesign cycles and ensures consistent, accurate engineering across the project.

Façade Design

Our Façade Design service delivers complete engineering solutions for modern cladding and building envelope systems. We develop system concepts, assess material options, and perform detailed structural and thermal analyses to ensure performance, safety, and durability. Coordination with architectural, structural, and MEP teams ensures seamless integration into the building design. We address panelisation, joints, mounting systems, water management, and expansion behaviour, producing fully detailed models and drawings ready for fabrication and installation. Whether working with metal façades, composites, GRC/UHPC, or bespoke geometries, our team prioritises efficiency, aesthetics, and lifecycle performance. The result is a façade solution that balances visual ambition with practical constructability and cost-effectiveness.

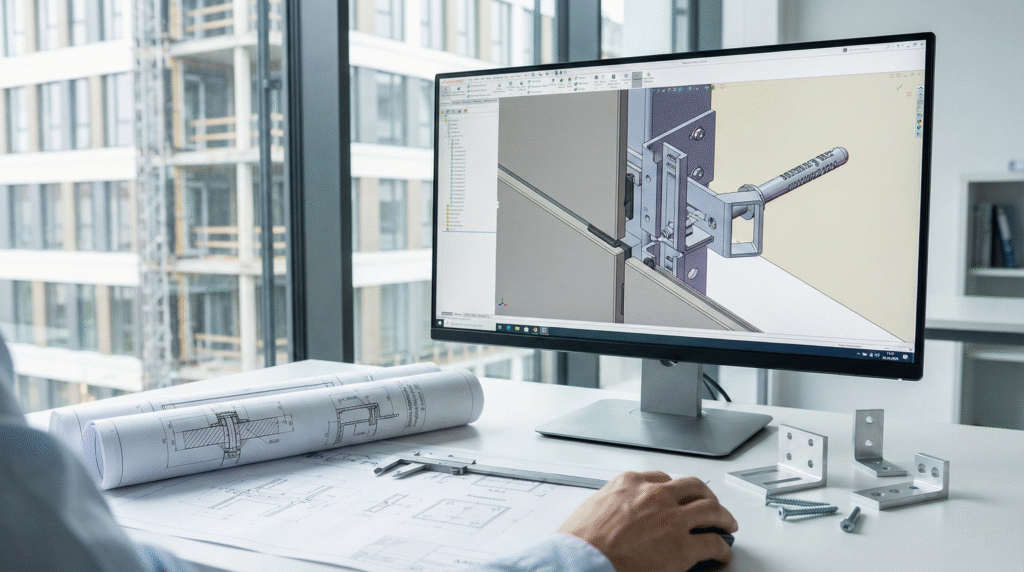

Fixation System Design

We design precise and reliable fixation systems for façade panels, cladding elements, ornaments, and lightweight structures. Our process includes bracket design, anchor selection, load-path evaluation, and compatibility assessments with substrate conditions. Each solution is engineered for safety, constructability, and tolerance management, ensuring secure installation with minimal on-site adjustments. Using 2D/3D modelling, structural checks, and coordinated interface studies, we ensure every fixation detail aligns with industry standards and fabrication capabilities. We also provide installation schematics and assembly documentation to support contractors during execution. Our fixation designs streamline manufacturing, reduce installation risks, and ensure long-term stability of architectural and façade systems.

Value Engineering

Our Value Engineering service enhances project efficiency by identifying opportunities to reduce cost, simplify construction, and optimise performance without compromising design intent. We evaluate alternative materials, façade systems, structural layouts, and production methods to achieve more efficient solutions. Through material rationalisation, simplified connection strategies, and optimised panel or component layouts, we improve constructability while maintaining or improving durability and aesthetics. Our process includes performance checks, feasibility evaluations, and detailed documentation of proposed improvements, enabling clients to make informed decisions. By bridging architectural vision with engineering practicality, we help deliver projects that are economically sustainable, technically sound, and easier to fabricate and install.

Detail Design and Documentation

Shop Drawings

We produce highly accurate shop drawings that translate design intent into clear fabrication and installation instructions. Each drawing includes precise dimensions, material specifications, joint and connection details, tolerances, and assembly sequences. Our documentation integrates directly with 2D/3D models to ensure consistency and minimise errors during manufacturing. Coordination with architectural and structural teams ensures every component fits correctly within the overall design. We tailor our drawings to fabrication processes—whether CNC, casting, cutting, or manual assembly—ensuring smooth production workflows. By presenting information logically and in a fabrication-ready format, our shop drawings reduce rework, support quality control, and help contractors deliver with confidence and efficiency.

As-built Drawings

Our As-built Drawing service delivers accurate documentation reflecting the final constructed condition of the project. Using site redlines, survey data, updated models, and installation records, we consolidate all changes made during construction into a clear, unified set of drawings. These documents provide essential reference information for facility management, maintenance planning, compliance audits, and future modifications. We ensure each drawing accurately represents installed dimensions, material adjustments, routing changes, and any deviations from original plans. Presented in a clean and organised format, our as-built packages help owners and operators maintain long-term project integrity while ensuring technical clarity for future teams.

Production Design

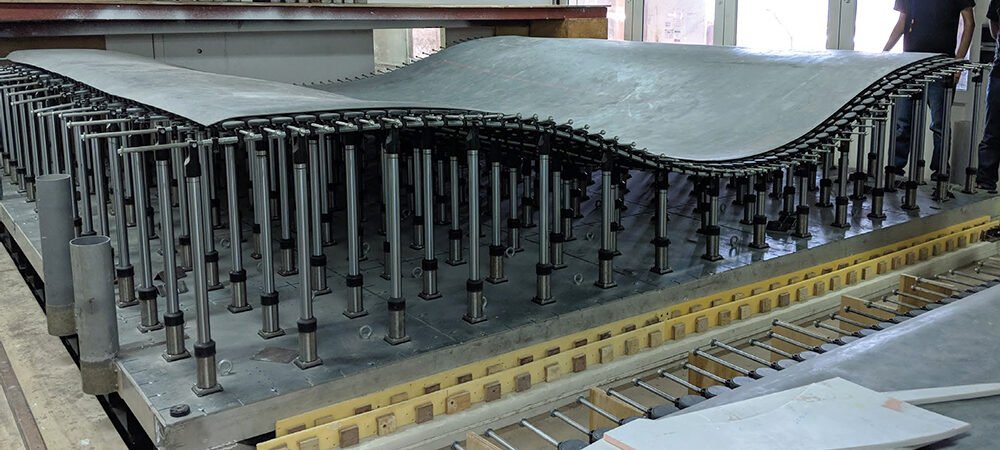

Our Production Design services convert detailed models into fully manufacturable data tailored to fabrication workflows. We generate CNC-ready files, casting mould information, unfolded sheet patterns, production assemblies, and material preparation layouts. Every component is reviewed for feasibility, tolerances, and compatibility with factory capabilities. Clear exploded diagrams, part numbering systems, and fabrication instructions support efficient workshop processes. By bridging design and production, we reduce interpretation errors, improve quality, and shorten lead times. Our outputs enable manufacturers to move directly from model to production with confidence, ensuring precise, repeatable, and cost-effective fabrication.

BOMs and Material Take-offs

We create detailed Bills of Materials and accurate material take-offs that support procurement, costing, production planning, and project tracking. Using coordinated models and structured data workflows, we ensure every component and material is correctly identified and quantified. Our reports include dimensions, weights, specifications, and categorisations aligned with fabrication and construction needs. We also provide revision control and update BOMs as design evolves, ensuring full transparency for stakeholders. These outputs help minimise waste, prevent procurement delays, and ensure accurate budgeting from early planning through final production.

Digital Modeling & Automation

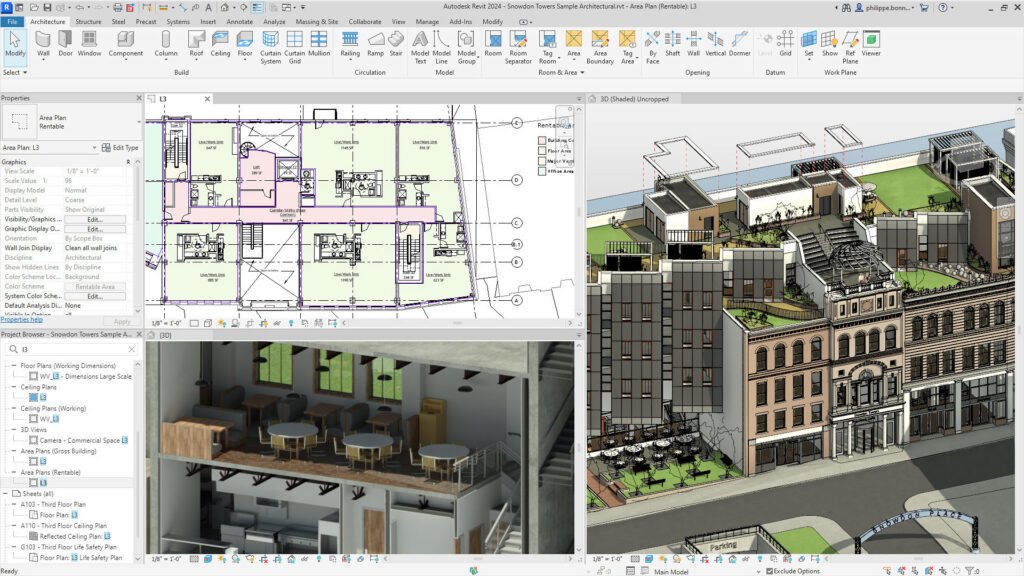

BIM/Revit Modeling

Our BIM/Revit Modelling service provides structured, high-quality models that support coordination, clash detection, quantification, and documentation. We develop models using consistent naming conventions, clean hierarchies, and industry-standard templates to ensure reliability across multidisciplinary workflows. Architectural, structural, and façade elements are modelled with careful attention to detail, enabling accurate extraction of drawings and schedules. Our BIM outputs integrate seamlessly with consultants, contractors, and fabricators, reducing coordination issues and improving design clarity. Whether for early-stage design or fully detailed construction packages, our models enhance decision-making, streamline communication, and support efficient project delivery.

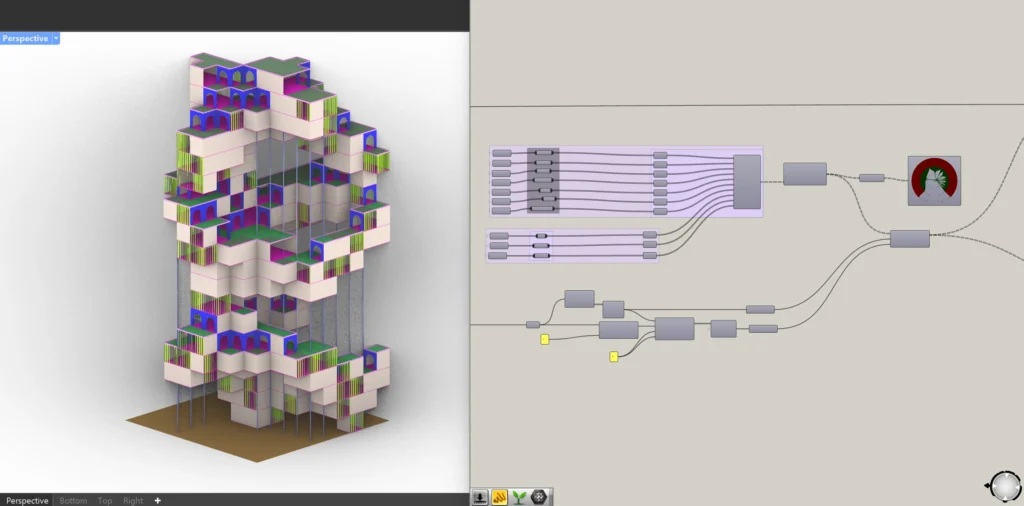

Design Process Automation via Macros (Grasshopper)

We use Grasshopper and parametric tools to automate repetitive and complex design tasks, improving efficiency, accuracy, and consistency. Custom scripts handle façade panelisation, geometric transformations, structural patterns, component generation, and data-driven optimization. Automation significantly reduces manual modelling time, especially for projects involving large numbers of repetitive elements or complex surfaces. Our tools also enhance design exploration by allowing rapid iteration based on parameters such as performance, cost, or geometry. By integrating automation into the workflow, we help teams deliver faster, reduce human error, and unlock more creative and technical possibilities within the design process.

Special Structures and Façades

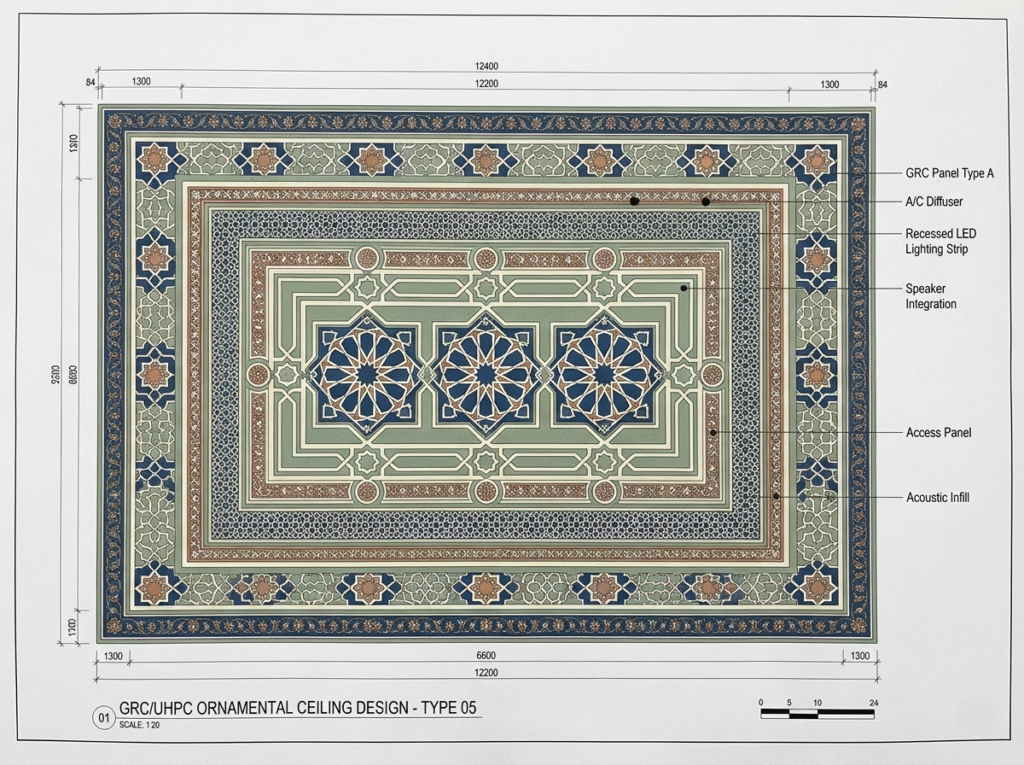

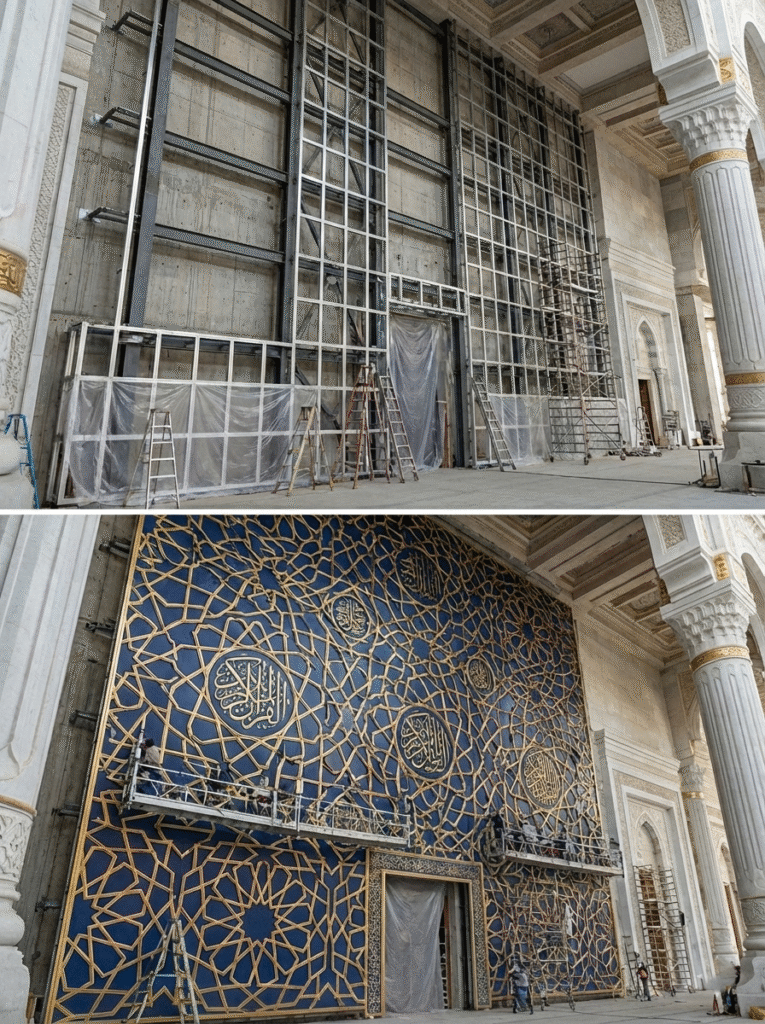

GRC/UHPC Façade & Ornament Design

We specialise in designing GRC and UHPC façades and ornamental architectural elements. Our service covers panelisation strategies, reinforcement layouts, mould design, anchor systems, and installation coordination. We ensure components meet structural, durability, and aesthetic requirements while remaining efficient to manufacture and install. Using advanced modelling tools, we handle complex geometries and intricate surface patterns with precision. Our approach aligns architectural expression with practical fabrication constraints, resulting in lightweight, strong, and visually refined façade solutions suitable for both traditional and contemporary projects.

GRP and Lightweight Structure Design

We design GRP and other lightweight architectural structures, supporting applications such as cladding, canopies, roof features, and custom forms. Our work includes structural assessment, layering strategies, connection design, fabrication considerations, and tolerance management. Lightweight systems require detailed attention to stiffness, anchoring, and surface stability, which we address through careful engineering and documentation. We deliver models, drawings, and fabrication details that ensure accurate production while providing the flexibility needed for visually expressive architecture. Our designs balance strength, weight efficiency, and manufacturability, enabling practical implementation of unique architectural features.

Composite Façade and Panel Design

Our composite façade services support a wide range of panel systems, including ACM, honeycomb, fibre-reinforced, and other custom sandwich constructions. We develop layouts, joint strategies, backing structures, and fixation details tailored to the behaviour of composite materials. Structural checks, thermal considerations, and installation sequencing are incorporated into every design package. By coordinating closely with fabricators and installers, we ensure panels fit precisely, perform reliably, and maintain consistent surface quality. Our expertise enables the delivery of lightweight, durable, and highly adaptable façade solutions for buildings of any scale.

Let’s Bring Your Idea to Life

Get in Touch

If you have any questions or would like a project quote, please email us at info@crafizsolutions.co.uk or use the contact form.