Product Development

Transforming ideas into innovative, manufacturable, and market-ready products.

Product Lifecycle Management

Product Development

Our Product Development service guides ideas from concept to market-ready solutions with efficiency and precision. By integrating design, engineering, and lifecycle management, we ensure every stage—concept, prototyping, testing, and launch—flows seamlessly. Leveraging PLM platforms, our team enables secure collaboration, version control, and traceability across global teams. The result is reduced time-to-market, improved product quality, and greater alignment between design intent and final delivery.

Cost Estimation & BOM

Accurate planning drives successful production. With our Cost Estimation & Bill of Materials (BOM) service, we provide detailed, structured insights into materials, components, processes, and labor. We generate intelligent BOMs linked directly to CAD models, ensuring updates flow automatically as designs evolve. Cost estimation tools highlight opportunities to reduce material waste, optimize suppliers, and align with budgetary constraints. This service helps you make informed decisions early, control project spend, and achieve predictable, cost-effective outcomes.

Change Management

Managing design changes effectively is critical in complex product development. Our Change Management service provides structured workflows for handling engineering change requests (ECRs) and engineering change orders (ECOs). Using PLM tools, we ensure full traceability, impact assessment, and stakeholder alignment before changes are approved. This reduces errors, eliminates redundancy, and accelerates implementation while keeping regulatory compliance intact. The outcome is streamlined collaboration, controlled costs, and consistent delivery of up-to-date product data.

Manufacturing & Prototyping

Design for Manufacturing (DFM)

We help you design smarter from the start. Our Design for Manufacturing (DFM) service ensures that every product concept is optimized for cost-effective, high-quality production. By evaluating factors such as materials, tolerances, manufacturability, machining or molding constraints, and production processes, we identify and mitigate issues early—in design, not on the shop floor. The outcome? Simpler parts, fewer defects, lower tooling and material costs, faster production cycles, and more predictability. Whether it’s for high-volume injection molding, sheet-metal fabrication, CNC machining or additive manufacturing, our engineers ensure your design is feasible, efficient, and primed for scaling.

Design for Assembly (DFA)

Assembly doesn’t have to be complex. With our Design for Assembly (DFA) service, we streamline your product so that it’s easier, faster, and more reliable to put together. We reduce part-counts, select standard components where possible, design parts for better fit, alignment and handling, and think through how fasteners, joins or interfaces work—whether manually or by automation. The result: less labour, fewer assembly errors, improved consistency, lower per-unit assembly cost, and often quicker time to market. Our DFA work usually runs in parallel with DFM so that the whole manufacturing + assembly chain is efficient.

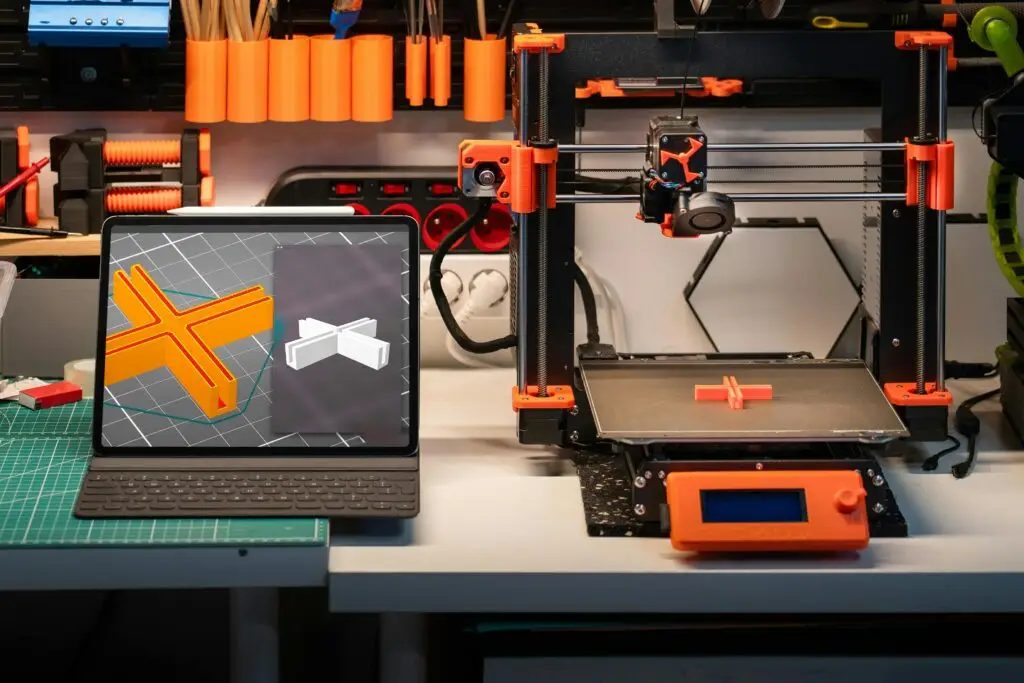

3D Printing & Rapid Prototyping

Bring ideas to life quickly. Our 3D Printing & Rapid Prototyping service transforms concepts into working physical models, functional prototypes, or appearance models with speed and flexibility. Using a variety of additive technologies (e.g. SLA, SLS, FDM, DMLS or equivalents), we offer a wide choice of materials, finishes, and post-processing options. This enables you to test form, fit, function — iterate designs — long before full-scale production. Rapid prototyping also reduces risk, as early issues get exposed in prototypes rather than expensive production parts. Whether for one‐offs or small batch iteration, we deliver precision, speed, and tangible feedback to validate design choices.

Manufacturing Drawings & Supplier Data Packs

A strong design is only as good as its documentation. Our Manufacturing Drawings & Supplier Data Packs service ensures your parts enter manufacturing without ambiguity. We produce detailed, precise drawings—including all necessary views, tolerances, materials, finish specifications, notes, and GD&T as required—aligned with relevant international standards. Alongside, the supplier data packs provide everything your suppliers or manufacturing partners need: bill of materials (BOM), material specs, surface finish, any vendor-approved components, test or inspection criteria, packaging/assembly info, and version history. This reduces back-and-forth, prevents costly production errors, speeds supplier onboarding, and helps ensure that the final product matches your intended design exactly.

Technical Documentation

Product Development Documentation

Our Technical Documentation services provide a complete, structured foundation for successful product development—from defining technical requirements and analysing risks with FMEA, to building robust DVP&R plans, engineered test strategies, and statistically driven DoE studies. We prepare certification-ready documentation, installation and O&M manuals, system interface diagrams, graphical task cards, service bulletins, and capability analyses that improve clarity, reduce errors, and support every stage of engineering, manufacturing, and lifecycle management. Each deliverable is crafted for precision, traceability, and compliance, ensuring seamless communication across teams and smooth regulatory approvals.

To explore each service in detail, visit our full Technical Documentation section.

Let’s Bring Your Idea to Life

Get in Touch

If you have any questions or would like a project quote, please email us at info@crafizsolutions.co.uk or use the contact form.